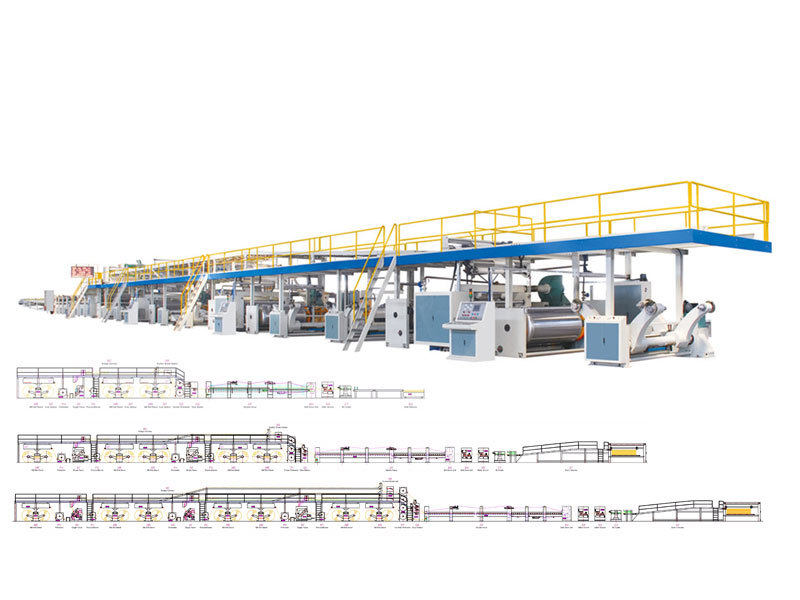

Function and characteristic

● Mechanical speed: 200m/min, 250m/min.

Effective width 1900mm to 2600mm.

● Can store 999 sets of orders, achieving automatic or manual order replacement without stopping the machine.

● Quick order change, with a change time of 3-8 seconds. Using two machines together can achieve immediate order change without slowing down.

● Automaticaly track the speed ofthe producion line to ensure synchronization, and can be connected to the producion management svstem with strong compatibility pressure sdjustment(optional).

● The upper and lower computer control systems are composed of high-qualtyimported industrial computers and high-periomance programmable controllers.

● There are three types of wire pressing: convex to concave (thre layer ine, convexto concave (five layer line), and convex to flat. The three types of wire pressing canbe electically converted. The depth of the pressing wheel can be automaically controlled by a computer, with good line shape and easy bending.

● Using a thin tungsten steel alloy knife with a sharp blade and a service life greater than 8 million long meters.

● Knife sharpening is a computer-controlled automatic or manual sharpening tool that can be cut while sharpening, improving production eficiency.

● Adopting imported synchronous driving device, with accurate accuracy, long service life, and low operating noise.

Technical data

| Model | 2200 | 2600 |

| Machine dimension(mm) | 3700×1700×2340 | 4100×1700×2340 |

| Power(kw) | 16 | 16 |

| Max slitting width(mm) | 1900 | 2300 |

| Min slitting width(mm) | 140 | |

| Min scoring width(mm) | 0 | |

| Scoring height(mm) | 0-10 | |

| Blade(mm) | Φ200×122×1.2 | |

| Blade&Scoring composed type | Five blades eight scoring | |

Keywords

Computerized Thin Blade Slitter Scorer Machine(Zero Line Pressing)

Contact Us

Classification