Main featrues

● The whole machine is designed and manufactured according to the high demand, reliability function and safety production.

● Selects the high quality materials and accessories, all the drive rollers adopted high quality steel materals, hard chrome plating and the surface treated by surface grinding.

● Fixed units, each unit adopts the vacuum adsorpion type conveyer, printing unit topping adopts servo control, to achieve precision printing network.

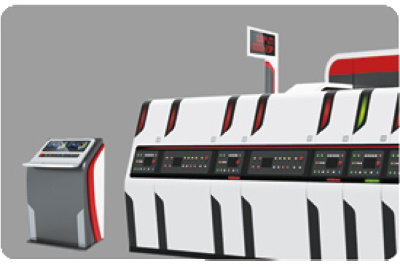

● The machine adopts PLC touch screen control, can be stored and reuse the ordered data, it can change rapidly ,operate more convenient.

● Remote detection of faults can be realized through the network, and equipment faults can be quickly eliminated.

● Automatic zero and automatic reset.

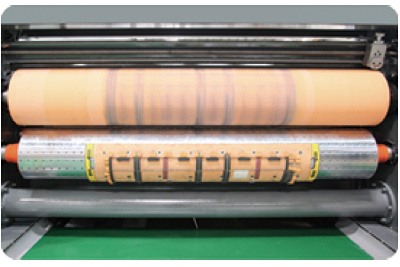

● Transfer roller impression cylinder, the clearance of anilox roller is controlled by computer.

● It adopt the paper central dust collection system.

Technical data

| Project/Type | RS920 | RS924 | RS1224 | RS1228 |

| Maximum speed(piece/min) | 350 | 280 | 250 | 230 |

| Maximum feed size(mm) | 900×2100 | 900×2500 | 1200×2500 | 1200×2900 |

| Minimum feed size(mm) | 300×600 | 300×600 | 350×600 | 350×600 |

| Size of drawing paper(mm) | 1200×2100 | 1200×2500 | 1500×2500 | 1500×2900 |

| Maximum printing area(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

| Thickness of standard printing plate(mm) | 7.2 | 7.2 | 7.2 | 7.2 |

| Maximum die size(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

Lead feeder unit

● Can be continuous or skip paper ( with counter).

● lt adopt the lead edge roller to feed, can adjust the route, to ease the pressure on paper feeding roller.

● Lead edge feeding increase the section flow rate to make feeding smoothly and accuracy.

● Frequency conversion control vacuum air flow and pressure, to match the board size.

● Paper feeding rubber roller adport for double glue, soft inner and outer hard, keep the inner elastic andguarantee the surface wear resistance, reduce the cardboard was be squashed to be be sent in.

● Dust pumping device:The brush and blower to remove cardboard surface confetti.Multiple fan straightpumping added electrostatic brush and tuming round brush, the greatest degree remove dust board surface.

● About paper roller ciearance, the position of the left right bar is adjusted by computer.

● Equipped with brush device to sufficiently eliminate dust and scraps as well as foreign substances on theprinting surface and to improve printing quality.

Printing unit

● Scroll hanging version,locking 360 degrees, let operation of hanging plate is simple, more accurate registration.

● Changing plate quickly,it can fix the incline error when paste the plate, so that reach to the range of am endment.

● Adopting vacuum absorb and high precision to convey, high printing precision.

● The fixed group be widen in printing unit,,it can help dry the ink,to guarantee the printing precision.

● Printing roll phase adopt servo motor to drive,can connect to the Endat high precise encoder,guarantee thecontrol precision of the servo drive system,topping-control contact to the servo directly,quick response andhigh precision.

● The transverse phase ,computer and electric-digital control.

● lmported brand scraper ink system link cavity body for non-metal material, special never rust, easy to clean;Rapid change around the blade.

● Adopt automatic cleaning -switching device .Let the ink recycling more thoroughly and save the ink,whenciean or change the color of the ink,can save ink 0.4-0.5kg per unit once.

Polishing unit

● The fixed group be widen of the varnish unit ,it can help speed up the oil-dry.

● You can adopt water base or UV varnish to polish when the varnish unit works, also to use as printing unit.

● Equipped with card sensor to make the operate safe and reliable.

Drying unit

● With servo motor driving ,guarantee not effect the printing precision.

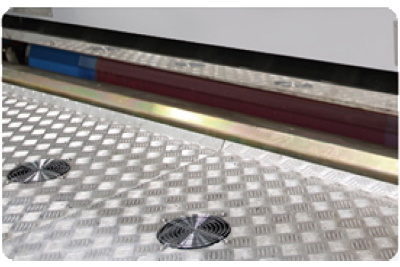

● Drying unit can adopt Infrared or ultraviolet light system.

● According to the wide of paperboard, you can segment control infrared lamp, energy saving.

● Uv drying method can dry the UV oil of presswork quickly,Avoid phenomenon of tow flowers die cutting. At the same time effectively improved the product printing speed.

Die cutting unit

● With the servo motor drive,guarantee the shake of printing unit is few,to make print accurate.

● Rubber gasket roll compensation is controlled by independent motor drive, rubber mat roller speed.compensation scope+ 3.5 mm, make the rubber gasket roller and die cutter roller speed is consistent.

● Rubber gasket roll machine screw reversing 50 mm winding device, improve the service life of the rubber gasket.

● Transverse phase, computer and electric control, digital control in the plus or minus 10 mm.

● Die-cutting phase adjustment by PLC, servo drive.

● The structure of the rubber gasket roller, keep the rubber gasket surface is flat and level

Keywords

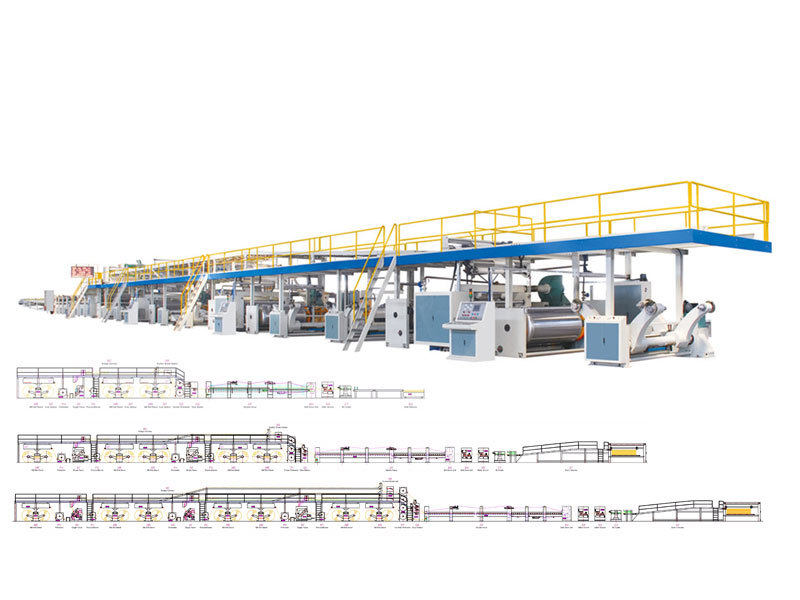

RS Series (Full Vacuum Adsorption Type Printer Series)

Contact Us

Classification