Function and characteristic

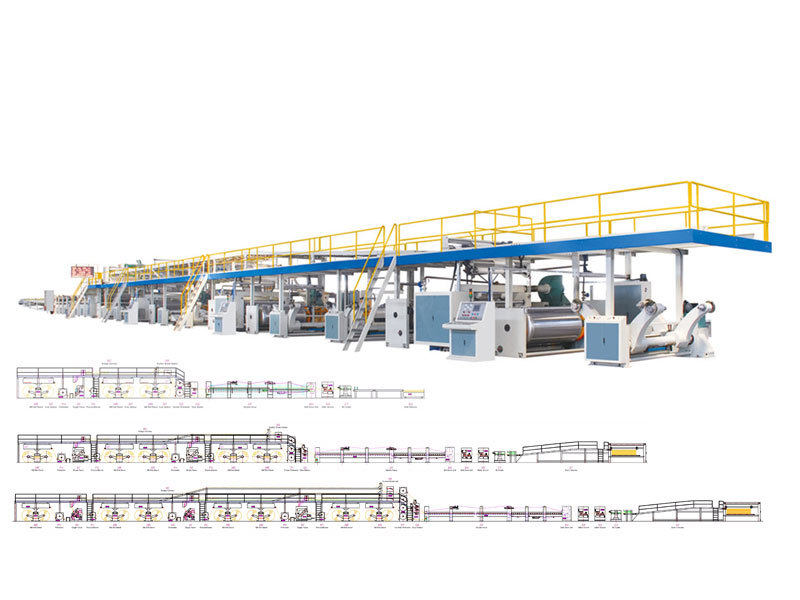

Intelligent automatic naling machine is composed of 5 parts: vacuum paper feeding section, line pressing section, gluing folding section, nailing box section and counting stacking output section.

All motors are made of Taiwan Shengbang motors except frequency conversion motors. Frequency conversion speed regulation, standard PLC touch screen control (double PLC, double touch screen), the whole machine electric adjustment,only need to input three data (length, width, height dimensions) on the touch screen, the machine automatically adjusted tothe position. The operation is simple and reliable, the naiing part and the gluing part can be controlled separately, the highest speed of gluing box is 180m/min, and the average speed of gluing box is 150m/min; Naiing box 4 nalling 70 pieces/min. High speed energy saving and labor cost saving.

Technical data

| Model | QS2600 | |

| Sticky box | Nailing | |

| Max.papar size(A+B)×2(mm) | 2600 | |

| Min.papar size(A+B)×2(mm) | 420 | 900 |

| Max.carton length A(mm) | 900 | |

| Min.carton length A(mm) | 130 | 270 |

| Max.carton width B(mm) | 650 | |

| Min.carton width B(mm) | 80 | 180 |

| Max.paper height(C+D+C)(mm) | 1200 | |

| Min.paper height(C+D+C)(mm) | 170 | 300 |

| Max.cap size C(mm) | 350 | |

| Min.cap size C(mm) | 50 | |

| The minimum height D(mm) | 100 | |

Keywords

Intelligent Automatic Folder Gluer Stitching Machine

Contact Us

Classification